For my first rolling cart with a workbench, I designed the height specifically so that it would match up with my DeWalt 7491 table saw on its rolling stand - as outfeed for longer material.

The combination was great, and I was able to cut some longer and larger pieces that would not have been possible on the small table of the 7491, by itself.

A little time went by, and I gained access to full-size cabinet table saws - one at the Dog Island workshop, and the other at my local community center woodshop. My garage philosophy changed, and I figured that having access to these saws meant that I didn’t need to have the 7491 taking up space in the garage. (Even when the legs are folded down, the 7491 and rolling stand combined occupies a pretty significant footprint.) So I sold the first WRoC cart and the 7491 as a package, and put together the Packout cart as my second Workbench Rolling Cart. The material for the 2nd WRoC was broken down at the Dog Island workshop, and assembled in the garage.

More time passed, and I realized that getting to the Dog Island workshop or the community center meant scheduling time in advance. And acting as a steward for open woodshop nights meant actually fulfilling the role of steward - it wasn't an open license to monopolize the table saw. 😦 I don't begrudge this - working with people on their projects is both a teaching and learning experience. But a little more instant gratification of table saw access would be nice.

I considered that I didn't want to get the size of another 7491 + Jobsite Stand. And the Festool CSC SYS 50 - while compact and efficient - was just a huge dosage of gateway drug that would end up with Systainers everywhere and renaming my kids Sascha and Husqvarna. But right around this time I found a great sale on the DeWalt 7485 - an 8 1/4" compact jobsite table saw. And it fit the size profile of being easiest to stash in a small garage, and the functionality profile of being able to handle 90% of the material I usually work with. So I picked one up, hoping that I could sneak it in the garage and bring it out discreetly for a couple of quick cuts.

The 7485 is smaller and lighter than the 7491. It certainly doesn't blast through thick walnut, but it does plywood just fine. It comes with a stand that does a decent job - nothing like the 7491 stand, but adequate for quick jobs when there is a level floor to place it on. But I started considering that it would be nice to pair it with the Packout WRoC, to act as an outfeed table. The stock 7485 stand was nowhere near the correct height, so how to align the 7485 table to match with the WRoC workbench?

There are lots of plans and projects available for compact stations for jobsite table saws. A search through Etsy will produce dozens of excellent designs with different sizes, storage options, and integration with other key woodshop tools.

It would be pretty trivial to modify the height of a station to raise the 7485 up to match the workbench. height. But then I'd be left with the 7485 permanently sitting on a rolling cabinet. If I matched the footprint of the station with the 7485 footprint (to keep it small), then it might be a little top-heavy and prone to tipping.

And if I made it larger than the 7485 - perhaps with some additional table wings to increase the infeed size - then I'd be making something that takes up more space in the garage. Tricky compromise.

The WRoC workbench does have dog holes, and I considered something like the Smart Cradle from Ron Paulk's Smart Woodshop.

I liked the idea of a cradle that attaches directly to the workbench. The height could always be matched to the outfeed, and it could be kept light.

But, the cradle would still need to be stored somewhere in the garage - so that's a small drawback to this solution. Also, the other component of my table saw 'stuff' is a medium-sized tool box filled with push sticks, featherboards, riving knives, etc. A cradle on the workbench doesn't eliminate the need for accessory storage. So I did not immediately jump in the direction of a cradle connected to dog holes.

The February 2002 issue of Workbench Magazine showed me something interesting - plans for a knock down table saw station. It was designed to act on its own, with outfeed arms and accessory storage built into the station. And I realized that - if the height of the station was stretched upwards - the table saw surface could be placed right at the height of Workbench-minus-7485 level.

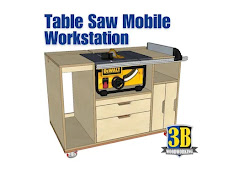

So back to Sketchup! From the table saw station design, I discarded the outfeed arms and the knobs to hold the table saw down to the surface of the station. Because the height went up, I increased the width and depth a little to ensure that the geometry was resistant to tipping. The fold-out legs and the lid had to be increased in length, but once this was done, the design looked solid.

With the station, and its integrated storage compartment, I consolidated the OEM table saw stand, and the toolbox containing the table saw accessories (push sticks, featherboards, riving knives, and the spare blades) into a single component that took up a modest amount of space when stored, and deployed to a full stand for the 7485 saw.

(Note made just before publishing. The compartment for storing accessories is 2 1/2" deep, which is fine for blades, featherboards, and push blocks. However, one of my purchased push blocks is 2 3/4" wide. In hindsight I should have piled all my table saw accessories on the workbench, and designed the compartment bigger to match their fit. But in this case I used the table saw to trim the push block a little narrower. It felt a little sacrilegious pushing a bright orange push block through the table saw, but c'est la guerre.)

The Table Saw Stand/Storage Unit is a little chunky, but stores and deploys easily and is stable enough to work solo if no outfeed is needed.

The design can also be easily adapted for other configurations and table saws. Does your workshop have a Sjobergs workbench and a Sawstop compact jobsite saw? Or a hand-built table and a Grizzly G0869 benchtop saw? Workbench height minus table saw tells us how high this table saw stand needs to be. We do custom work!

This solution fit my sweet spot:

- A workbench that did not have a fixed location in the small shop

- A compact table saw that stores in the garage and comes out when needed

- Outfeed alignment of the table saw and the workbench surface, in any location that the material requires

- Consolidation of table saw and accessories into a single place

It's possible that your garage would benefit from a similar solution! Dog Island Offcuts would be happy to hear about your configurations, and it would be fairly trivial to get another variation of this stand out into the world.

Comments

Post a Comment